What is the Polyjet process?

The Polyjet printing process is also known as Multi-Jet-Modeling (MJM) and is one of the additive printing processes. Polyjet printing works in a similar way to an inkjet printer – with the difference that instead of applying two-dimensional ink to paper, a three-dimensional object is created using liquid photopolymers in a layered construction process. In the context of rapid prototyping, the Polyjet process is popular because UV light quickly solidifies the photopolymers and thus the printed object is ready in a short time.

How does the Polyjet process work?

Before printing, special CAD software calculates along which lines the photopolymer and in which areas support structures are injected onto the worktop. The base material used for this process is UV-light-sensitive photopolymers.

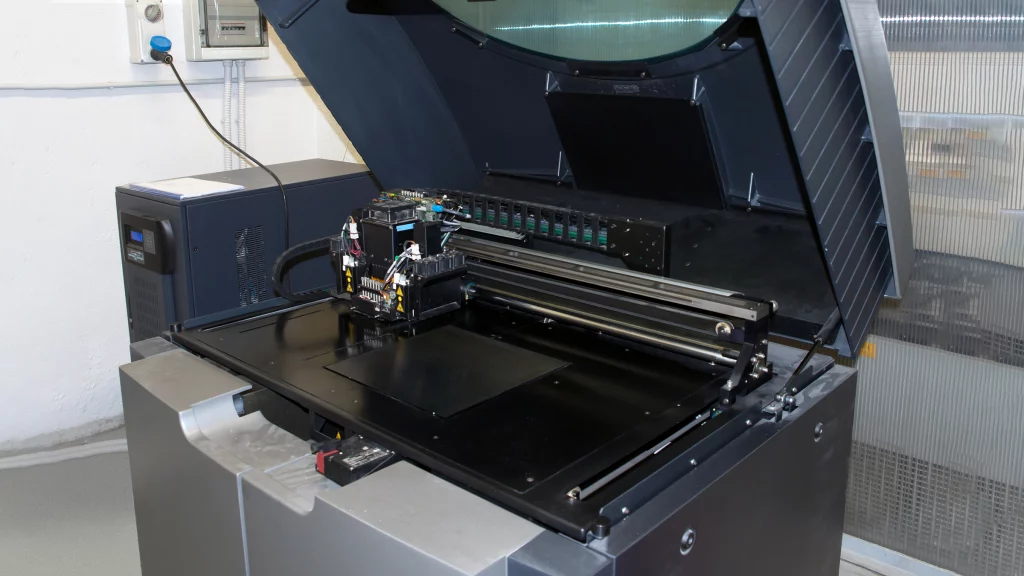

Once the object to be printed has been created in the CAD program, the data is sent to the printer. Here, the print head sprays or jets the liquid starting material along the specifications with several nozzles in tiny droplets onto a movable printing plate. At each step, the liquid photopolymer is cured simultaneously with the help of UV light. The UV lamp is mounted directly on the print head. The printing plate then moves down by the thickness of the applied layer. Now the next layer of curing polymers can be applied – until the object specified in the computer is ready.

What do you have to pay attention to in the Polyjet process?

3D printing with Polyjet technology is a free-space process: support structures are required that must be digitally calculated beforehand. These support structures can then be removed manually with a water jet or by a special solution bath.

The Polyjet process allows a mix of materials during a printing process. The UV-light-sensitive polymer is available in various colors as well as transparent. The design of multi-coloured parts is therefore no problem.