Startseite » Additive Manufacturing Plastics

We are a 3D printing pioneer from the very beginning. For more than 30 years, we have been manufacturing additive plastic components. And we are still excited about the wide range of possibilities offered by selective laser sintering SLS with plastic.

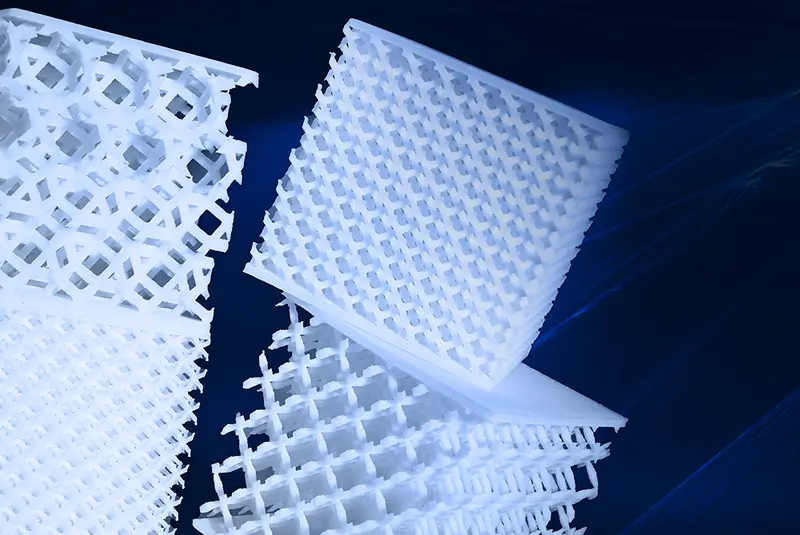

Our goal is to always break new ground and find new solutions for additive manufacturing with plastics. The 3D printing process we rely on is powder-bed-based laser beam melting (LPBF: Laser-Powder Bed Fusion). In the additive manufacturing of plastics, we use selective laser sintering (SLS). With its great design freedom and high productivity at low unit costs, it offers clear advantages. However, our ambition goes beyond pure 3D printing. As a full-service 3D printing service provider, we supply functional, perfectly finished and assembled plastic parts on request, which can be installed directly in series production, for example.

We carry out more than 8,500 orders per year on 28 SLS machines. Thanks to our intelligent project planning and project management, we always react quickly and flexibly, even with complex orders. We always deliver on time and at the agreed time. Since we are constantly maintaining and expanding our machinery, we can also provide larger SLS printing capacities at any time.

If you’re asking yourself the make-or-buy question, why not combine the two sensibly? We can provide you with advice and support through our claim to proven technology leadership and our focus and experience in the powder bed. Thanks to very efficient construction job combinations of different parts made of the same material, we manufacture cost-efficiently and quickly.

FKM Machinery 3D Plastics Production

Particularly heat-resistant, hard, resilient or even elastic? The requirements for plastic components are as diverse as our plastic powder portfolio. We have a wide variety of high-quality 3D printing materials ready for you and advise you on the selection if necessary.

We currently use the following 3D printing plastics: PA 12 natural/white/grey, PA 11 natural/black, PA 12 filled with glass, PA 12 with flame retardant, PA 12 with aluminium, PA 6, TPU and the high-tech polymer PAEK / PEEK.

Overview of Plastic Materials

SLS 3D printing of plastic parts offers completely new design possibilities compared to injection or die casting. That’s why when designing a plastic part to be additively manufactured, start from scratch and think creatively. For example, be inspired by nature and use ideas from bionics. Work with round rather than angular component shapes. Think about where mechanical forces actually act on the component and where material can be reduced. The SLS process also makes it possible to integrate functions into the component and combine several parts into one.

Our design recommendations summarize what you should consider when developing plastic components for 3D printing.

Design Tips for Plastic Components

Surface technology is the key to series production

The FKM full-service portfolio in the field of surface technology

In our surface technology department, we put the finishing touches on your 3D-printed plastic components. We optimize the component surfaces with different finishing processes depending on the required properties. These include coloured infiltration (dyeing), coloured painting, compaction blasting, vibratory grinding (trowalisation), gas- or watertight infiltration and machining.

We are setting new standards in the surface treatment of laser-sintered plastics with the specially developed FKM smooth® process. This stands for a particularly uniform and complete surface treatment.

Assembly of laser-sintered plastic parts

In our assembly department, we make your 3D-printed plastic parts complete. To ensure that they can be used immediately as fully functional and installable components in your series production, we assemble standard thread sets and other standard purchased parts into SLS components, for example. In prototyping, we glue several SLS components to produce the desired prototype.

Surface Technology Plastics

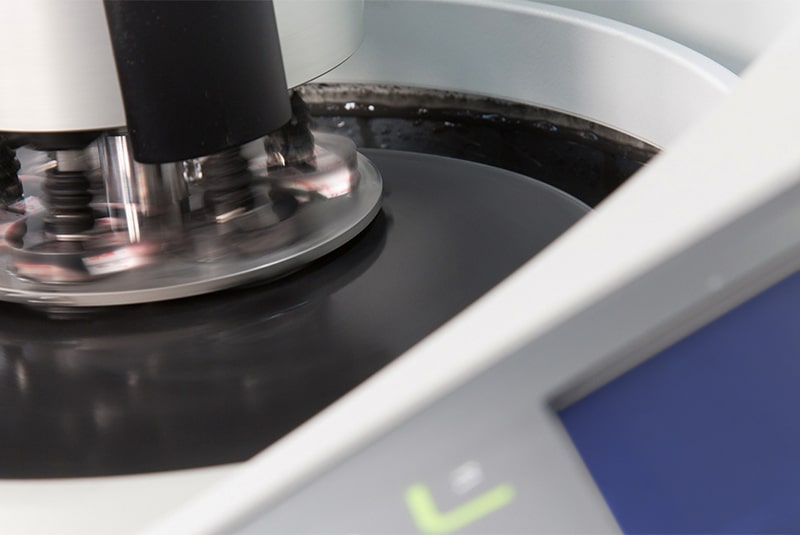

Our customers rely on the consistently high quality of our 3D printed plastic parts. However, this does not come by itself, but is monitored and checked by us day by day. Our quality management process involves several stages. It ranges from process validation before 3D printing to monitoring the ongoing 3D printing process and component control after printing. The printing process and the materials used are also documented.

With our in-house testing laboratory, we have been setting standards in AM quality assurance for many years. We inspect the 3D-printed metal parts with optical measurements, tensile tests, density measurements, shore hardness measurements and surface roughness investigations. In addition, we constantly control the quality of our 3D printing powders with the help of special particle measurements.

Get in touch with your team of specialists

Would you like a personalised offer or advice?

Get in touch with us!

FKM is a pioneer in selective laser sintering (SLS) and selective laser melting (SLM) in Germany and Europe. Since 1994, we have been part of a revolutionary rethinking process in the industry. Where tool and mould making used to determine the design rules, additive manufacturing with SLS and SLM is now changing entire production processes.

Sign up for our newsletter and receive free innovation news about industrial 3D printing.

Sie haben Fragen?

Nehmen Sie zu uns Kontakt auf.

Do you have any questions?

Please get in touch with us.