Startseite » Expertise » Design recommendations » Design recommendations for plastics

Plastic components measuring up to 910 x 430 x 405 mm in size are manufactured in one piece in a single operation. By adding individual elements, assemblies of any size can be produced.

If components are too large for our installation space, we cut the CAD data and glue the components together after the construction process. The glued seam can be reinforced with fibreglass mats.

We generally manufacture components with a layer thickness of 0.1 or 0.15 mm. The minimum wall thickness is approx. 0.5 mm in Z and approx. 0.7–0.8 mm for vertical surfaces. Both minimum wall thicknesses depend on the geometry of the component in question. Feel free to contact us to find out more!

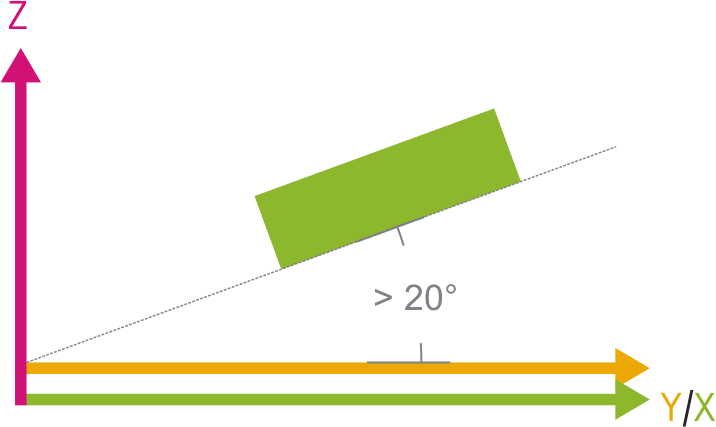

Steps in the component

If a construction plane is aligned with an angle of less than 20° to the X/Y plane, clear layers can be seen on the surface. The steeper the angle, the finer the steps.

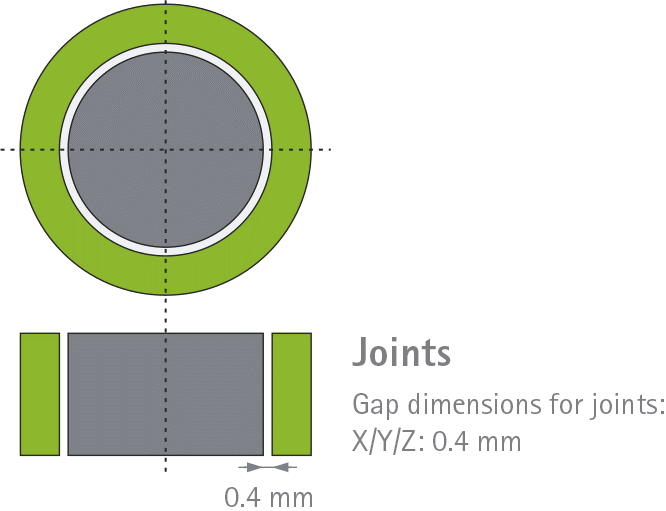

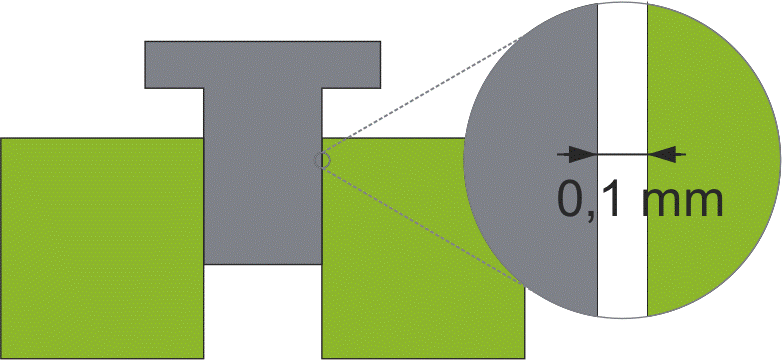

Loose connections

0.1 mm spacing is required for loose connections. Without a gap between a male and female component, a press fit is created.

Powder removal

Residual powder should be removable. but is difficult to remove in the case of long and thin pipes and parts with complex internal structures. The easier the powder can be removed, the shorter the post-processing time.

Tolerances

The tolerances depend on the material used and the component geometry.

In most cases, the following values can be assumed:

Smaller tolerances may be possible depending on the component geometry. In such cases, further consultation with FKM is required.

Geometry-dependent distortion is possible because laser sintering is a thermal manufacturing process.

The tolerances specified above do not apply to holes. Bore dimensions are generally slightly smaller than required.

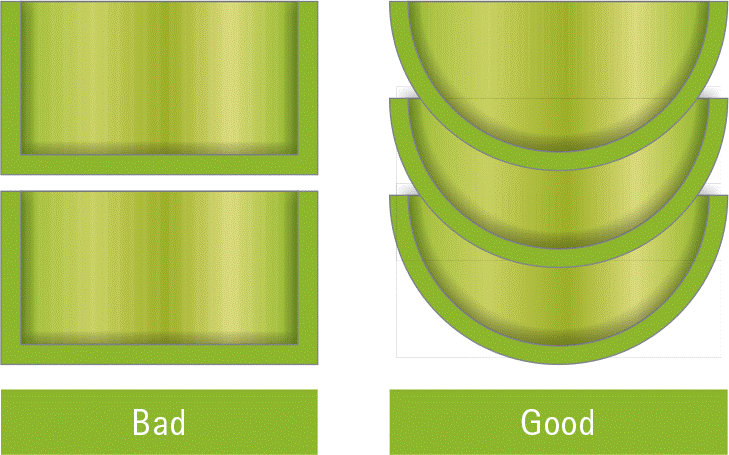

The costs depend on the overall height (Z direction), which in turn determines machine hours and powder consumption.

Significant cost savings can be achieved with the following design measures:

Reducing the construction volume

Reducing the overall height:

Diversity. Diversity thanks to six plastics and filled polymers

What material-related user advantages are required? Tensile strength, break resistance, temperature resistance, bending flexibility and lightness?

Whatever components you need to produce, FKM has the right material to meet every requirement. Make the most of our experience – together we will find the right material for your application.

With a comprehensive material selection of pure or filled plastics, large-volume and flexible 3D printing capacities and validated parameter sets, we reliably achieve optimum product properties for your parts.

Would you like a personalised offer or advice?

Get in touch with us!

FKM is a pioneer in selective laser sintering (SLS) and selective laser melting (SLM) in Germany and Europe. Since 1994, we have been part of a revolutionary rethinking process in the industry. Where tool and mould making used to determine the design rules, additive manufacturing with SLS and SLM is now changing entire production processes.

Sign up for our newsletter and receive free innovation news about industrial 3D printing.

Sie haben Fragen?

Nehmen Sie zu uns Kontakt auf.

Do you have any questions?

Please get in touch with us.