Startseite » Expertise » Design recommendations » Design recommendations metal

Metal components measuring up to 400 x 400 x 360 mm or 400 x 800 x 500 mm (aluminium) can be manufactured in a single operation.

To optimise costs, laser melting can build solid components with different wall thicknesses (hollowed out) depending on their geometry:

Dimensional and shape tolerances depend on the geometry of the components. As a rule, production is carried out in accordance with the general tolerance standard DIN ISO 2768-m.

Fittings and threads should always be produced by means of a machining finish. The allowance for a machining finish must be at least 0.5 mm (or even higher, depending on the geometry of the component).

“Feel free to discuss these application examples with us. We will be happy to provide you with our advice and assistance.”

Support-free setup

When working with metal, each component must be fixed to the base plate. This fixation is also known as support and is used for both heat dissipation and mechanical stabilisation.

Furthermore, support geometry is required at points at which a contour is not melted on a previous contour (but instead into a loose powder bed) or where the area to be exposed deviates very strongly (>45° or a radius of >3 mm) from the previous layer. In most cases, the support structure is a honeycomb structure with the smallest possible wall thickness, which can be easily removed by hand in the outer area of the component.

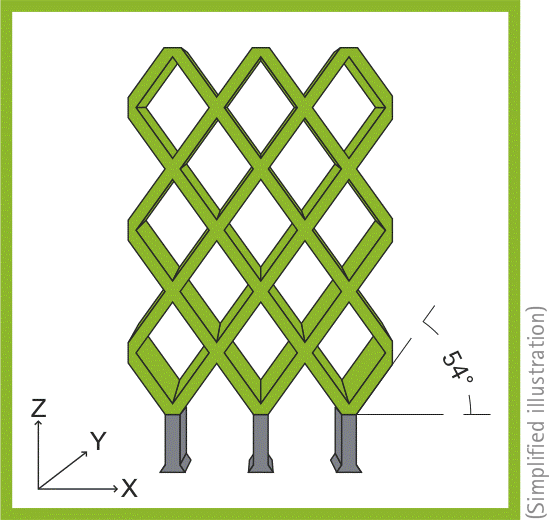

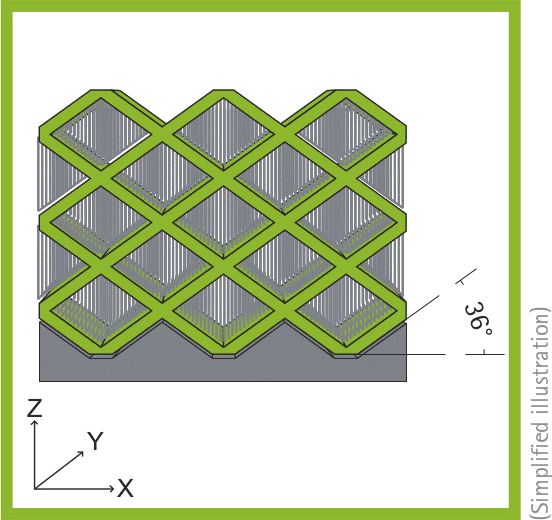

The illustrative images below show how differently a component can be built up in this process and what effects the direction of assembly can have.

On the left, the component (marked in green) is optimally aligned for the process, while the alignment on the right (rotated by 90°) is unfavourable to the process. The grey areas indicate the support structures required.

Hybrid design

When using the hybrid construction method, the component to be manufactured is disassembled into a substructure (hybrid part) and the actual SLM part.

For tool steel 1.2709, the following materials are suitable as base materials for the substructure:

If other materials are to be used as a substructure, stress cracks or detachment of the SLM part from the hybrid part may occur. The use of such materials therefore requires prior technical clarification by FKM.

“FKM recommends using the material 1.2709.”

Diversity. Six metals.

What material-related user advantages are required? Tensile strength, break resistance, temperature resistance, bending flexibility and lightness?

Whatever components you need to produce, FKM has the right material to meet every requirement. Make the most of our experience – together we will find the right material for your application.

Our comprehensive portfolio of highly developed metal materials has proven itself in daily practice. The modern metal powders ensure the desired product properties and make the reproductions reliably repeatable.

Would you like a personalised offer or advice?

Get in touch with us!

FKM is a pioneer in selective laser sintering (SLS) and selective laser melting (SLM) in Germany and Europe. Since 1994, we have been part of a revolutionary rethinking process in the industry. Where tool and mould making used to determine the design rules, additive manufacturing with SLS and SLM is now changing entire production processes.

Sign up for our newsletter and receive free innovation news about industrial 3D printing.

Sie haben Fragen?

Nehmen Sie zu uns Kontakt auf.

Do you have any questions?

Please get in touch with us.