Startseite » 3D printing & services » Additive Manufacturing Metal

3D printing metal has been our passion for decades. The possibilities of powder bed-based additive manufacturing fascinate us every day. With our services, we help to push the boundaries and drive innovation. Day after day, we work to break new ground and find solutions that make 3D printing and additive manufacturing even better, more economical and faster.

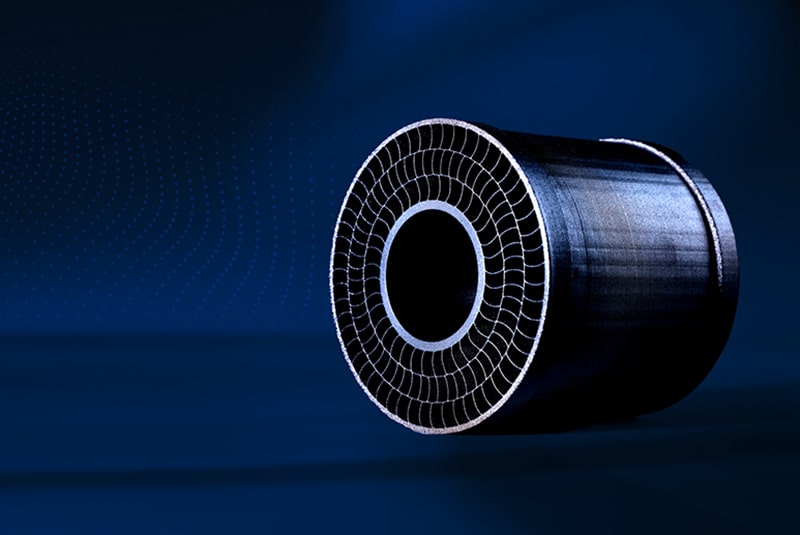

We rely on the processes of powder-bed-based laser beam melting (LPBF: Laser-Powder Bed Fusion). In this way, we specialize in a state-of-the-art technology that brings a new quality to the 3D printing of metal components. The process we use in metal production is called Selective Laser Melting (SLM). With SLM, we print tested, high-quality metal parts for prototyping, tooling and production from batch size 1. As a full-service 3D printing service provider, we also take care of the finishing and assembly. This enables us to supply thermally and mechanically resilient, ready-to-install components for design, toolmaking or the on-demand production of series parts and spare parts.

At FKM, we carry out more than 2,500 metal orders per year on 17 SLM machines.

Thanks to our intelligently managed project planning, we are flexible and adaptable. We guarantee short response times, transparency and 100% adherence to delivery and deadlines, even in complicated special cases. We continuously invest in our production facilities and can thus provide capacities for the additive manufacturing of metal at short notice and flexibly.

Since we efficiently combine different components made of the same material in our construction jobs, our prices are always competitive and often cheaper than in-house production.

FKM Machinery 3D Printing Metal Fabrication

For metal 3D printing, we always have a range of high-quality metal powders in stock. These include aluminum, stainless steel, tool steel, Inconel 718, cobalt-chrome and copper. Our metal specialists will be happy to advise you on the selection of the optimal 3D printing powder for the application areas of your metal parts.

Overview Metal Materials

Anyone who switches from conventionally manufactured metal parts to 3D-printed components has to think in a new way. The SLM process offers so many more possibilities that designers can give free rein to their creativity: How would nature do it? Where do curves instead of sharp corners, edges or angles make sense? Which mechanical forces act on the component and how, and where can material be saved? Is it possible to make one out of two or three components? And which functions can be integrated directly?

You can find out what needs to be considered when developing 3D printed parts in metal in our design recommendations.

Design tips for metal components

3D-printed metal components and metal tools already have very good surface properties after production. In order to further optimize them for a requirement profile, different surface technology processes are available for finishing. Since additively manufactured metal parts have a high density, mechanical post-processing or polishing is even possible down to the high-gloss range.

At FKM, you can also have your metal components heat treated (hardening), plasma or laser coated (short-term plasma nitriding), electroplated (nickel plating), coated or painted. In the case of internal support structures that are difficult to access, we offer the high-quality service of automated support structure removal plus component smoothing from a single source.

Finishing metal components

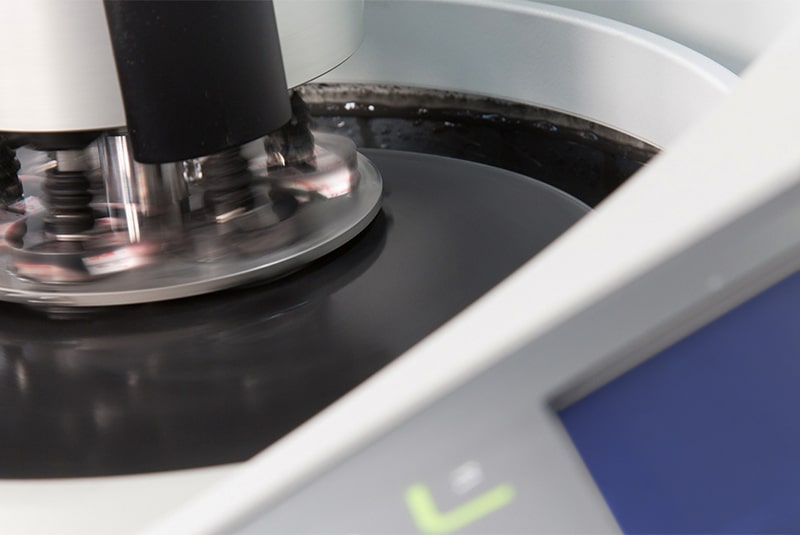

Our customers rely on the high, consistent quality of our metal 3D printed parts. However, this does not come by itself, but is monitored and checked by us day by day. Our quality management process involves several stages. These range from process validation before 3D printing, to monitoring the ongoing 3D printing process, to component control after printing. In addition, it includes the documentation of the printing process and materials.

Our in-house testing laboratory has been setting standards in AM quality assurance for many years. There, we put the 3D-printed metal parts through their paces. For this purpose, we use optical measurements, tensile tests, density measurements, shore hardness measurements and surface roughness investigations. We constantly check the quality of our 3D printing powders with the help of special particle measurements.

Quality Management & Quality Assurance

Would you like a personalised offer or advice?

Get in touch with us!

FKM is a pioneer in selective laser sintering (SLS) and selective laser melting (SLM) in Germany and Europe. Since 1994, we have been part of a revolutionary rethinking process in the industry. Where tool and mould making used to determine the design rules, additive manufacturing with SLS and SLM is now changing entire production processes.

Sign up for our newsletter and receive free innovation news about industrial 3D printing.

Sie haben Fragen?

Nehmen Sie zu uns Kontakt auf.

Do you have any questions?

Please get in touch with us.