Quest for Innovation

Future technologies, materials expertise and practical know-how from a single source

Potential, future, forecasts

The industrial additive manufacturing of metals and polymers is undergoing rapid development. The AMPOWER Report for 2023 assumes that the global market will grow by an average of 17.7 percent per year.

- Plastics are still ahead: the global market volume for additive 3D printing with polymers was EUR 6.5 billion in 2022, more than twice as large as metal printing at EUR 3 billion

- Metal is catching up rapidly: While the market growth for polymers will average 13 percent by 2027, the growth forecast for metal 3D printing is almost 30 percent per year.

One of the reasons for this is that the further development of metal-based 3D printing means that more sophisticated metal applications can now also be efficiently additively manufactured. Important innovations in the field of support structure-free laser melting are approaching and will significantly reduce costs. This will open up new economic applications, for example in medical technology or mechanical engineering.

Source: additive-manufacturing-report.com

© Copyright 2023, AMPOWER GmbH & Co. KG

The market for additive manufacturing is driven by several factors:

- the increasing need for faster and more efficient production,

- more efficient use of resources through less material consumption and more recycling

- and the ability to manufacture complex and customized products.

We are ready for these dynamic future developments and will be happy to provide you with advice and assistance in implementing your 3D printing tasks.

We receive the TOP 100 seal for innovative strength

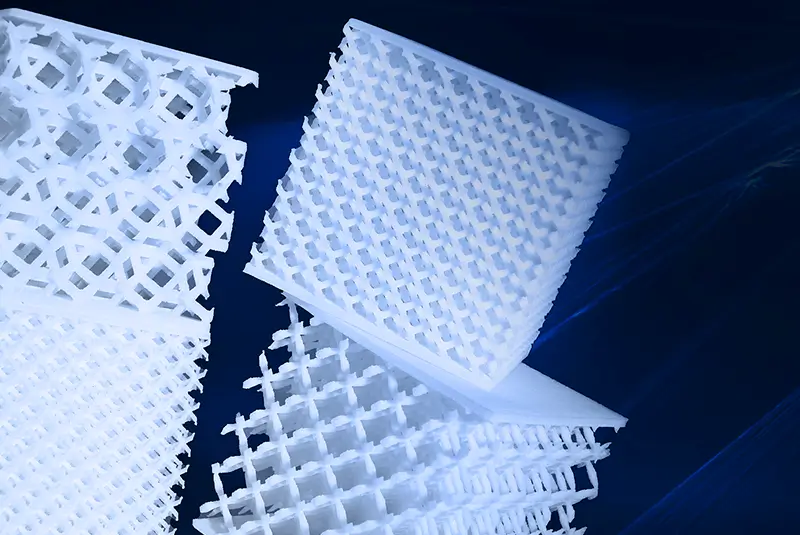

New materials in 3D printing

PA 613

PEKK 100

Fields of application by industry

Industrial 3D printing has developed enormously in recent years and enabled innovations in the following sectors, among others:

Automotive industry

Aerospace

3D printing of complex parts, lightweight components and rocket engines that are difficult to produce using conventional manufacturing processes

Medical technology

3D printing of customized prostheses, orthoses, implants, dentures and surgical instruments#

Industry

3D printing of complex components, prototypes of electronic components and housings, rapid tooling (tools and devices using 3D printing)

Sport and lifestyle

3D printing of sports equipment such as shin guards, helmets, shoes and rackets as well as spectacle frames with personalized fitting and individual design

FKM is your high-end 3D printing service provider

for ready-to-install parts made of plastics, filled polymers or metal.

From materials consulting and design optimization to joint project co-engineering, we are our customers’ experts and partners for tricky tasks. With our complete after-print service consisting of testing technology with IATF certification and a range of surface technology with various finishing processes, we have been offering 3D printing services as a complete solution for almost 30 years – from a single source, with a lot of understanding.