Startseite » 3D printing & services » Areas of Application & Advantages

The fields of application and advantages of our 3D printing are manifold. They range from the production of prototypes, toolmaking to the production of fully functional series components. Key benefits of 3D printing include:

Rapid prototyping is a 3D printing process with many advantages. It is used to quickly and cost-effectively produce a physical model or the prototype of a product. The basis for this is CAD data. The process is often used in product development to enable design iterations and bring the product to market faster and better.

Advantages & FKM Services in Rapid Prototyping

Rapid tooling is a process in 3D printing that offers important advantages. It makes it possible to quickly and cost-effectively produce tools and moulds for series production. Without rapid tooling, tools and molds often have to be produced through time-consuming and expensive processes such as milling. In rapid tooling, the tools or molds are first simulated on the PC. They are then printed directly from CAD data in the desired final shape.

Advantages & FKM Services in Rapid Tooling

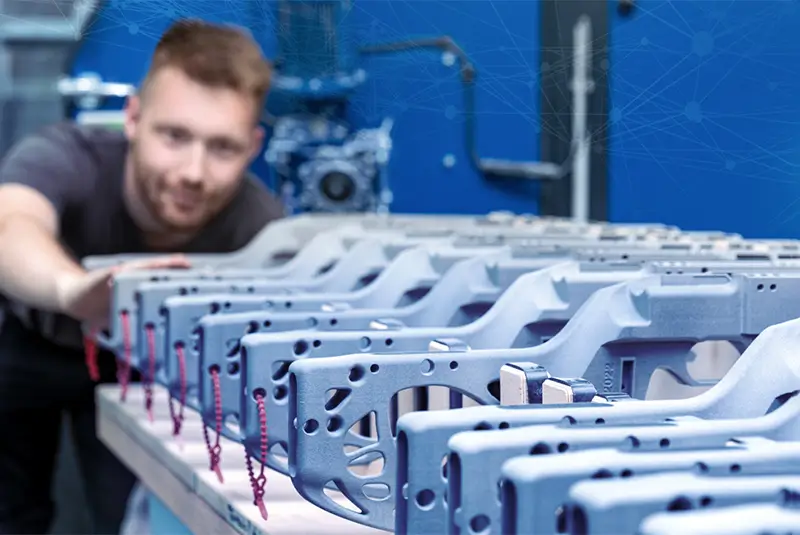

The production of serial and spare parts on-demand in 3D printing offers many advantages. It allows fast and cost-effective part production without expensive tools and molds. This allows companies to respond efficiently and directly to customer needs without having to build up large inventories.

In addition, 3D printing can be used to easily produce components with complex shapes and geometries. This also applies to parts that are difficult or impossible to produce using conventional manufacturing methods. Even spare parts that are no longer available or are no longer in production can be printed on-demand. This keeps older devices and machines running for a long time.

Benefits & FKM Services in Series and Replacement On-Demand

When is industrial 3D printing worth it?

3D printing brings economic benefits to the industrial manufacturing chain in terms of supply chain and design optimization. Additive manufacturing technologies show their advantages in

Industrial 3D printing allows for easy adaptation of CAD data, individualization and demand-based production, especially in small and medium-sized series.

Reduce installation effort and space requirements: Functional integration reduces the number of components and makes intelligent use of available installation space. This saves time and money.

Lightweight construction is becoming increasingly important across all industries. It helps to reduce material requirements, costs and weight and reduce energy consumption.

Complex geometries or bionic structures – industrial 3D printing opens up new possibilities, shapes and functionalities and realizes previously impossible ideas.

Sie haben Fragen?

Nehmen Sie zu uns Kontakt auf.

Do you have any questions?

Please get in touch with us.