PBF – Powder Bed Fusion / 3D Powder Bed Process

(Contents to follow)

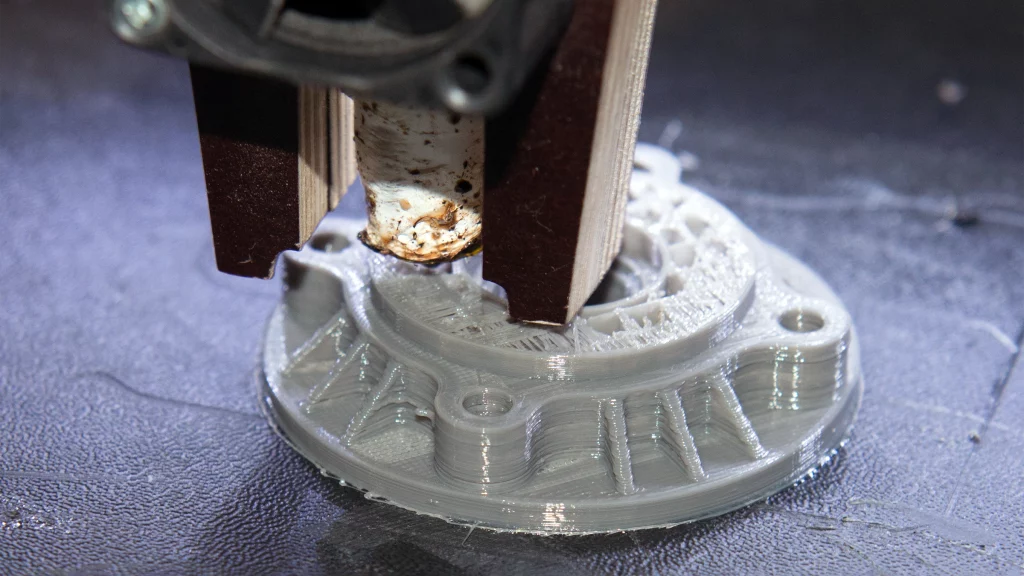

FDM – Fused Deposition Modelling

Fused Deposition Modelling, or FDM for short, is a special manufacturing process in which an object is made layer by layer from a meltable plastic. In addition to the SLS process, it is currently the most widely used process in the field of plastic 3D printing. In this printing process, the desired object is produced by melting filaments.

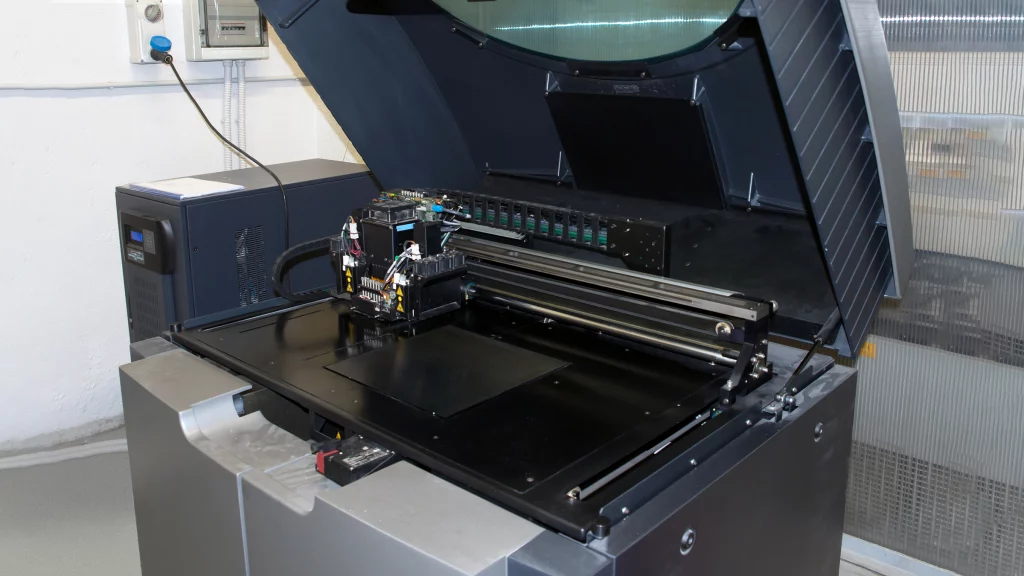

MJF / Multi Jet Fusion

The multi-jet process, also abbreviated as the MJF process, is one of the additive manufacturing methods. The developer is Hewlett-Packard (HP). The material is based on various powder-based plastics. This type of 3D printing does not work with lasers, as in the Polyjet process, for example, but with the help of special thermally conductive liquids, the so-called fusion agents.

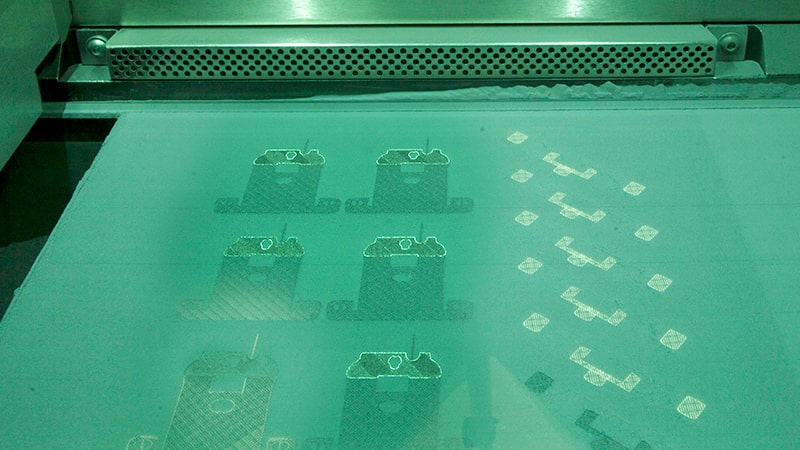

Polyjet

The Polyjet printing process is also known as Multi-Jet-Modeling (MJM) and is one of the additive printing processes. Polyjet printing works in a similar way to an inkjet printer – with the difference that instead of applying two-dimensional ink to paper, a three-dimensional object is created using liquid photopolymers in a layered construction process. In the context of rapid prototyping, the Polyjet process is popular because UV light quickly solidifies the photopolymers and thus the printed object is ready in a short time.

SLA / Stereolithography

Stereolithography, abbreviated as SL or SLA, is the oldest 3D printing process and was developed as early as the early 1980s. In this laser-based process, three-dimensional objects are created layer by layer in an installation space. The material is based on liquefied acrylic resins. In rapid prototyping, stereolithography is a frequently used process alongside the Polyjet process.

Laser Cusing

The LaserCusing® process is a patented three-dimensional laser melting process developed by Concept Laser GmbH. The word is made up of Concept Laser + Fusing. In this technology, three-dimensional objects such as components are built using 3D CAD data.

LPBF – Laser Powder Bed Fusion

Since then, a number of machines and systems for the 3D printing of metals have been developed by various companies based on the LPBF process – with different names for the same process principle. Among other things: