The LaserCusing® process is a patented three-dimensional laser melting process developed by Concept Laser GmbH. The word is made up of Concept Laser + Fusing. In this technology, three-dimensional objects such as components are built using 3D CAD data.

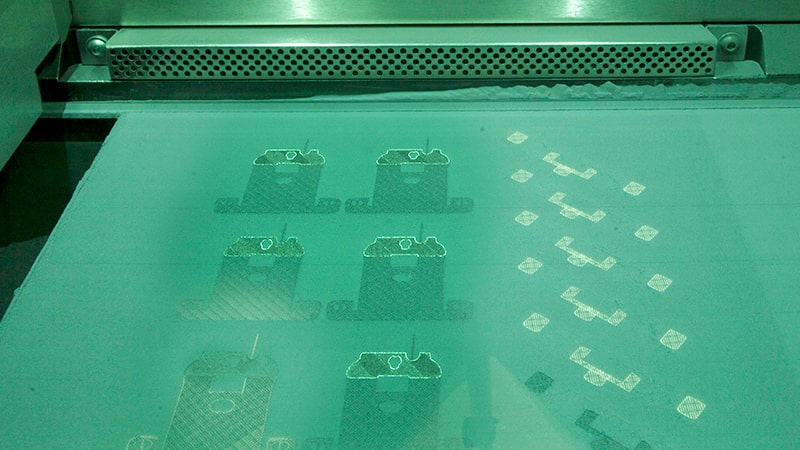

On a worktop, a thin layer (about 20 to 60μm) of the selected metal material is applied layer by layer in powder form. By means of a laser, which is guided via a mirror unit, the geometry of the component, which has previously been determined on the computer, is melted, layer by layer, until the object is completed. The surplus powder is reused for further processes.

As a result, and also due to the low emission values of the laser, LaserCusing® is a green technology. Complex structured components can be produced without tools. Even internal hollow or lattice structures are no problem for the process.

A special feature of the patented process is the reduction of stresses and the production of low-distortion, leak-proof components.

In order to prevent contamination of the material that impairs the result, LaserCusing® takes place under an inert gas atmosphere with argon or nitrogen.

The laser cusing process is based on the same principle as the laser melting® process. However, behind the brand name LaserCusing® lies the feature of stochastic control of the slice elements. This special feature reduces stresses and subsequent cracking during the production of large components. Parts created with the technology are of interest to various industries, from automotive manufacturing to dental prostheses.