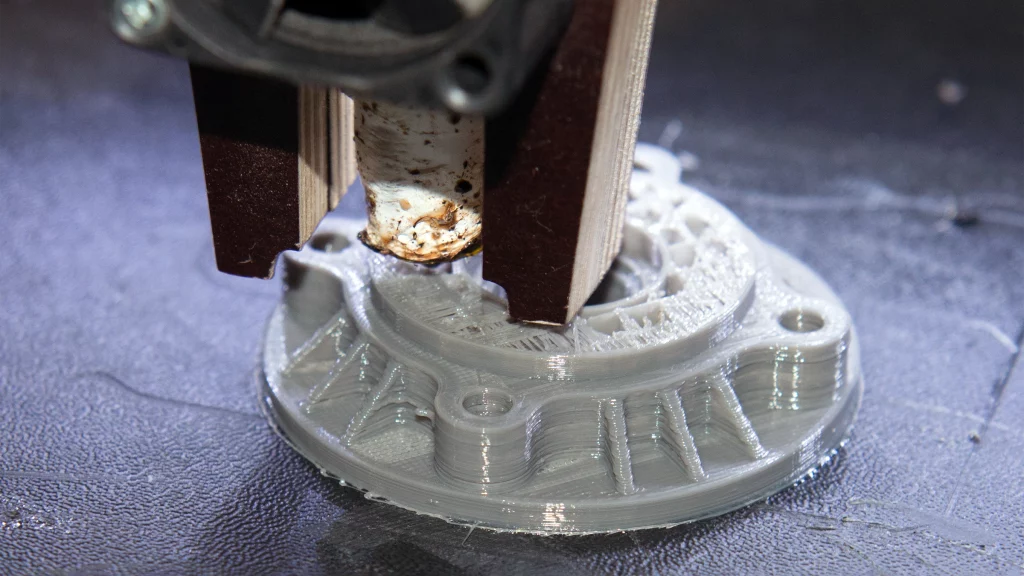

Fused Deposition Modelling, or FDM for short, is a special manufacturing process in which an object is made layer by layer from a meltable plastic. In addition to the SLS process, it is currently the most widely used process in the field of plastic 3D printing. In this printing process, the desired object is produced by melting filaments. These filaments are rolled up in wire form on rolls, heated up and extruded through a nozzle. Layer by layer, the previously digitally determined object is created on a lowering bed. In the free-space process, the molten filament is precisely placed via the nozzle. The set thickness of the layers to be melted determines the optical quality of the finished 3D print. The thinner each layer, the finer the surface structure.

Since FDM is a free-space process, more complex geometric shapes require support structures, which must be created during the digital preparation of the print. These support structures are manually removed at the end of printing so that the item can be further finished as needed. The polymer filaments are available in different colors. 3D printers that have two or more nozzles can be used to print multi-colored objects. In addition to the comparatively slow production, the poor connection between the individual layers is a common criticism of FDM technology.