Rapid prototyping

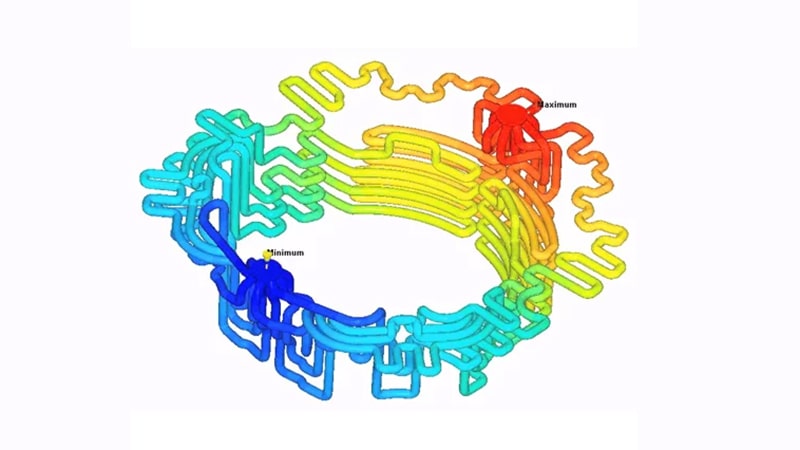

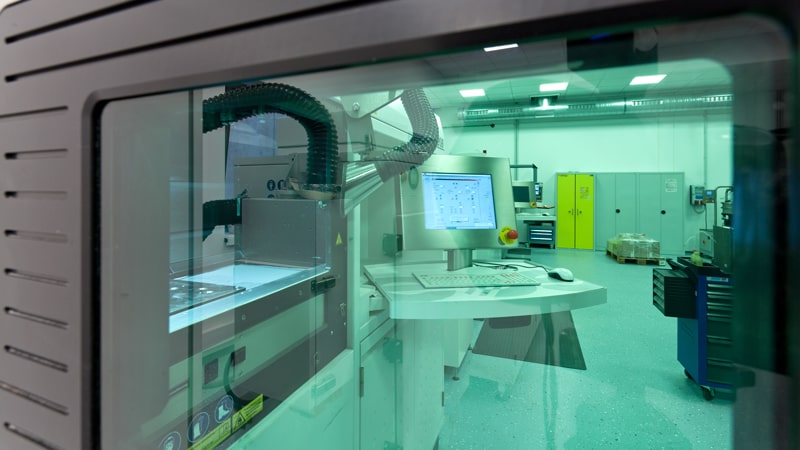

With rapid prototyping via SLS (Selective Laser Sintering) and SLM (Selective Laser Melting), you get time-efficient, functional and resilient functional prototypes. In this way, problems and weaknesses are identified at an early stage during development and the design or function can be digitally changed accordingly. With rapid prototyping components, projects are realized step by step, while at the same time minimizing the risk of sources of error in the end product and thus also the investment risk.

Rapid tooling

The term rapid tooling means something like “fast toolmaking” and is an umbrella term for various processes of additive manufacturing (AM; Additive manufacturing), in which tool components and inserts as well as hollow molds, for example for injection molding machines, can be produced quickly. And this is exactly where the difference to rapid prototyping is defined, a rapid model-making process of components and objects. This is because in rapid tooling, only tools and their components are printed three-dimensionally.

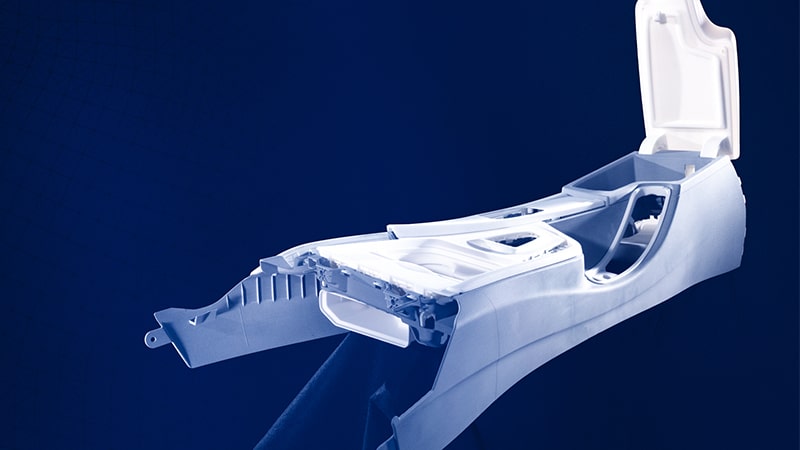

Prototyping

Prototyping refers to the three-dimensional production of functional prototypes (test models) of a planned product. Depending on the purpose and properties that are to be tested with the help of such a model during development, a prototype can correspond to the end product in purely visual or technical terms. A prototype is therefore used to check the appearance or functionality of a workpiece before series production begins. In this way, potential sources of error are detected and eliminated. Prototyping is an efficient way to extensively test and optimize new components.

Rapid Manufacturing

The term Rapid Manufacturing (German: fast manufacturing) is an umbrella term under which various processes for the rapid production of components are collected. The focus is therefore on the time- and cost-efficient production of fully operational end products – both as one-offs and in series. Rapid manufacturing includes additive and machining processes. For various reasons, FKM relies on additive manufacturing (AM) techniques SLS (selective laser sintering) and SLM (selective laser melting).