Industry-compatible 3D series production in plastic and metal - documented and audited.

Additive contract manufacturing that you can rely on - certified, suitable for industrial use, ready for series production.

Ready-to-install components from a single source: consulting, design optimization, 3D printing, surfaces & quality assurance.

- Variety of materials: high-end plastics & metals

- Certified: ISO 9001, ISO 14001, IATF 16949

- Precision & reproducibility according to industry standards

- Leading production capacity for plastic and metal in Europe

Why FKM sintering technology

Additive solutions for your industry

Whether automotive suppliers, medical technology, mechanical engineering or aviation - FKM stands for industrial 3D production that is reliable, certified and economical. Over 30 years of experience flow into every application - from prototype to series production.

Optimization of your components for function, costs and process reliability - before production.

Printing, post-processing, assembly and QA - for ready-to-install components from a single source.

In-depth understanding of function, tolerances and series production - from real proximity to classic manufacturing.

In-house measurement technology, material tests, sampling - much more than an AM service provider.

From the powder to the package, every process step is documented, recorded and archived.

“Additive manufacturing only really works if it is industrialized – with clear processes, stable quality and a real sense of responsibility. This is exactly what we aspire to at FKM.”

Start your project with FKM.

Whether you want to optimize an existing design or build a series - we accompany you from the idea to the ready-to-use component.

Customer testimonials

Results that convince

Our customers come from industries in which precision, reliability and adherence to deadlines count. Their experience shows what additive series production can achieve when it is implemented professionally.

Very short response times and feedback that really helps – that’s my experience with FKM Sintertechnik. Even if my project was ultimately too small for the company’s services, I can only recommend the company in terms of customer friendliness!

The 3D Printing metal department is absolutely amazing. Competent service, quick turnaround, reasonable pricing and most of all excellent customer service from Dennis Barke and his team. FKM’s other BU, the tooling store, still has room to grow.

Very good quality standards, competent contacts and friendly, cooperative interaction.

Very short delivery time, at a good price. Quick quotation, very friendly contact.

Great service, great employees! There is no problem that cannot be solved with FKM.

Highly collaborative, demonstrating quick responsiveness and strong engagement in projects. The quality delivered is consistently good, with competitive pricing on metallic materials

3D printing with substance

- 0

Liter

Plastic powder

daily - 0

Plastic systems (SLS, HSS, MJF)

- 0Metal

plants (SLM)

Projects

Additive solutions that exist in use

Our projects show how ideas can be transformed into functioning components - manufactured precisely, economically and ready for series production.

Plastic series production: 1,000 parts per day

Surface compaction

Chemical smoothing

Coloring / painting

Design for Additive Manufacturing

Function integration

Reduced number of parts

No assembly

Improved performance

Metal series production: 2,000 parts per month

Machining

Heat treatment

Polishing

Ready-to-install component: Orthosis

TPU, PA12

Chemical smoothing

Coloring

Assembly

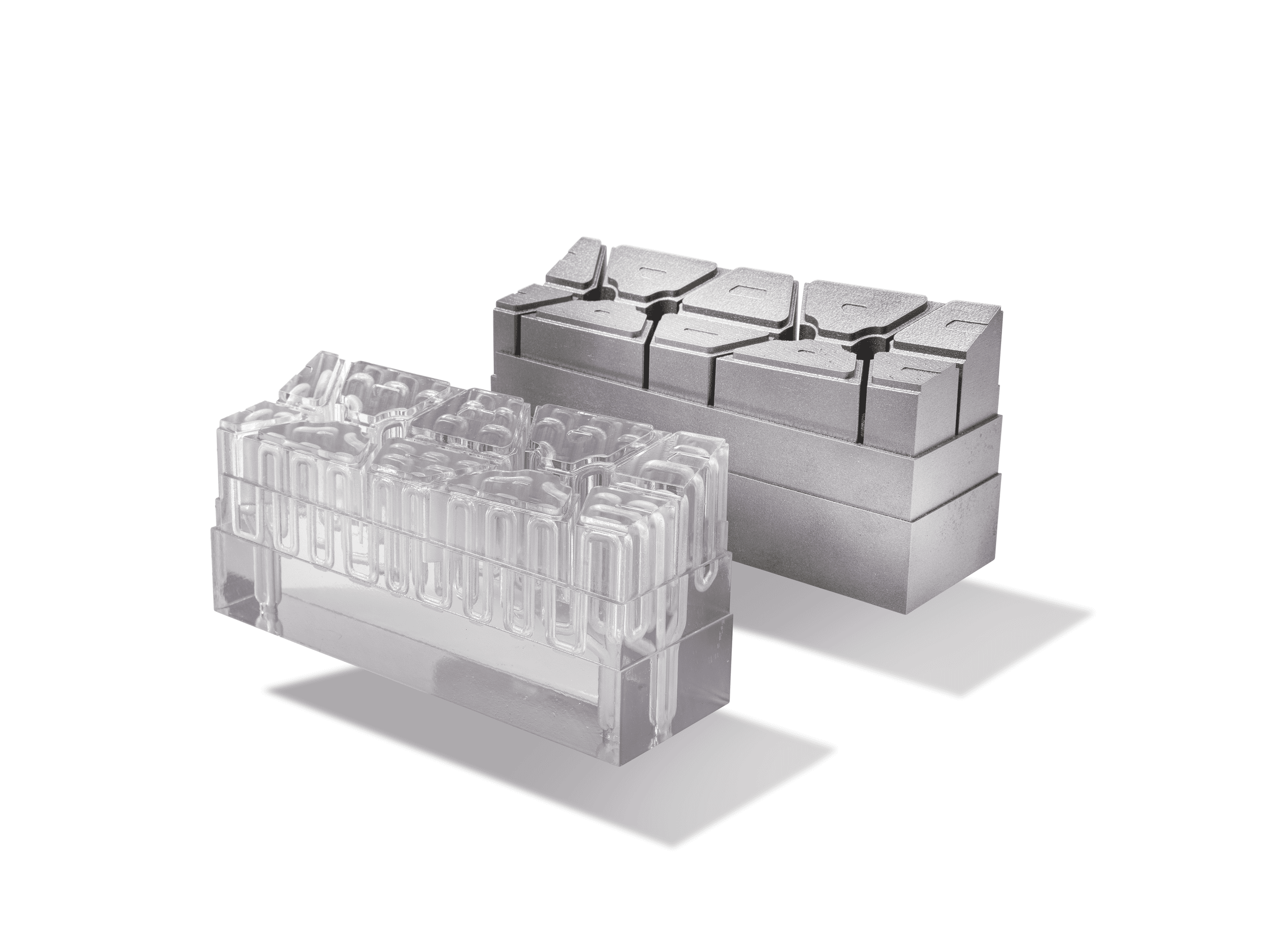

Tool with conformal cooling

Cooling close to the contour

Improved component quality

Shorter cycle times

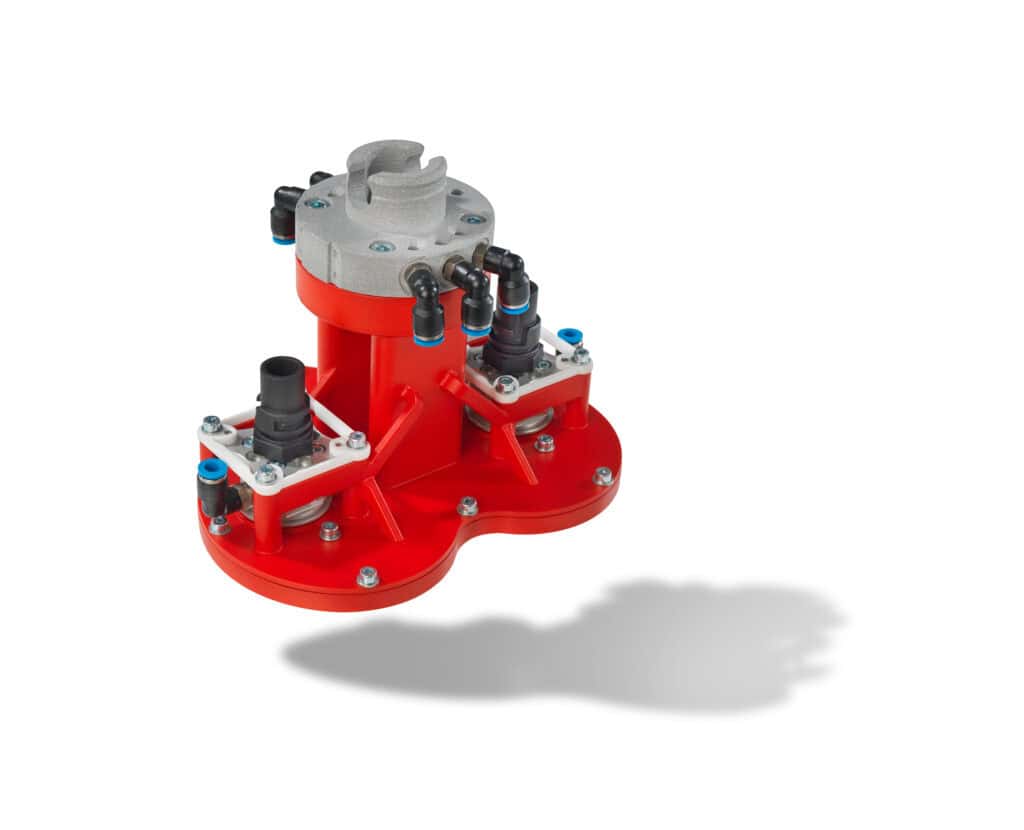

Ready-to-install component: Suction pad

PA12, Alumide

Chemical smoothing

Coloring

Assembly

Process

Our cooperation in 4 steps

Clear steps, transparent processes - from the first meeting to the finished component. Our process is structured in such a way that your project goes into series production safely and quickly.

- Step

Inquiry & project consulting

You send us your CAD data - we check feasibility, material and process and recommend the best way to implement it.

- Step

Design consulting & co-engineering

We analyze your component for 3D printing, identify optimization potential and recommend targeted improvements.

- Step

Production & quality assurance

Your part is created layer by layer - with monitored processes and tested precision to industry standards.

- Step

Delivery & integration

Reworked, tested and securely packaged - your component arrives on time and ready for use.

Take control of your project.

Good decisions start with an honest conversation.

Whether prototype, series production or new application - we provide you with personal, technically sound and honest advice.

We answer your questions

Here you will find answers to the most important questions about FKM.

We rely on state-of-the-art powder bed-based processes: selective laser sintering (SLS), high-speed sintering (HSS) and multi-jet fusion (MJF) for plastics and filled polymers as well as selective laser melting (SLM) for metals. This enables us to produce precisely fitting individual parts, functional prototypes, tools as well as series and spare parts – precisely, efficiently and on-demand at all times.

We process a wide range of materials: In the plastics sector, we use materials such as PA 12, PA 11, PA 613, PA 12 with glass beads, PA 12 with flame protection, TPU and PEEK. For metal components, we use aluminum, stainless steel, tool steel, copper, Inconel and cobalt-chrome, among others.

Our additive manufacturing processes are used in many industries – from the automotive and aerospace industries to mechanical engineering and medical technology. Whether functional prototypes, lightweight components or small series: We manufacture precisely, flexibly and individually according to our customers’ requirements.

As a full-service provider, we support you from consultation and design through to production and post-processing – including finishing, surface technology and testing laboratory. In addition, we are certified to ISO 9001, ISO 14001 and comply with the IATF 16949 standard in the automotive sector, making us ideally equipped for series and spare parts production under stringent requirements.